Integrated Rock Ripper Arm (Rock Ripper Boom, Rock Ripper Arm)

Integrated Rock Ripper Arm (Rock Ripper Boom, Rock R...

TEL:

+86-186-6891-6700Combined Rock Ripper Boom and Arm (Rock Ripper Boom, Rock Ripper Arm)

Combined Rock Ripper Boom and Arm (Rock Ripper Boom, Rock Ripper Arm)

General Information:

√ Combined rock ripper arm and boom products fit to 40tons~180tons excavators. It has over 10 years history on the development and manufacturing. Annual production capability 500 sets. Market sales volume of rock boom products since 2011 till 2019 reaches 2000 sets.

√ Applicable working conditions: Heavty duty breaking, digging and demoliations in mining, road construction, building demolition, salt lake, frozen soil stripping, quarries, tunnel construction, foundation crushing and working sites such as beaches, ditches, rivers, wetlands, etc., especially for sandstone, weathered rock, limestone, karst rock, etc., with a hardness below 7, The destructive effect is particularly significant comparing to the conventional excavators, dozers or similar rock booms in the market.

√ Product advantages: Wild application on excavators ranging from 40tons to 180tons, particularly suitable to heavy duty excavators above 80tons, simple structural design, strong breaking and digging force on hard terrains, low failure rate, low maintenance cost.

Product Development History

√ In Aug., 2011, the first set of rock boom was developed and applied for digging rocks.

√ In March, 2012, the first generation of rock boom products were put into production in batch.

√ In May, 2013, owing to the increasing market demands for the rock boom, excavator suppliers started to sell the excavator without front parts. a

√ In Nov., 2014, rock booms were shown firstly in Bauma, 2014, Shanghai, China.

√ In 2015, rock boom products were applied wildly to all kinds of working conditions and almost all the excavator brands and models ranging from 40tons to 180tons.

√ In 2017, total sales volume reached 2000 sets and sold to several overseas markets including Russia, Pakistan and Laos etc.

√ In Sept. 2018, The second generation of product, Diamond rock booms were shown in Bauma 2018, Shanghai, China, with completely new design and processing technology.

√ In Aug. 2019, Diamond rock boom series, were wildly sold and applied in the market.

Origin of Product Design

In 2011, the Leshan Angu Hydropower Project on the Dadu River began construction. The earth and stone works of this project were undertaken by our company, mainly to excavate the river bed and build the power generation tailrace channel of the hydropower station on the riverbed. This involves millions of cubic meters of red sand and gravel in the river bed to be broken and cleaned, and the hardness of the red gravel reaches the level of 5. Since the project cannot use explosion measures, we have considered and applied several options. One is hydraulic breakers, but its problem is that the working speed is very slow, the efficiency is low, and the investment of equipment to be put in is very expensive. Second is the Caterpillar D11 super-large bulldozer, which provided us with higher construction efficiency, but new problems continued to occur, as below:

√ The financial pressure for using large quantities of bulldozers is very high;

√ Insufficient digging depth;

√ The bottom unevenness of the construction caused very slow truck loading efficiency and travelling speed;

√ The bulldozer is unresponsive and has a high failure rate.

In order to solve these problems, improve work efficiency, and shorten the construction period, based on the excavators, we finally successfully developed the rock boom products. It is specifically suitable for rocks and hard terrain breaking and excavation, more flexible and powerful comparing to the tranditional excavators, dozers and similar rock booms in the markets.

After 8 years since the first generation of rock arms went on the market in 2011, the second product generation, the Diamond rock booms, has been successfully developed and widely used in the market, and has also been well accepted by customers. The Diamond rock booms adopts an innovative design, adjusts the gravity center of the product, and adopts an innovative limit block design and replacing the old I-frame design, which can increase the digging force by 10%, while providing 10% of the working speed, reducing the wearing of the bucket teeth and tooth seats, also reducing failure rate of the rock booms. The unique Dynamics technology guarantees the working stability and efficient working output of the Diamond rock booms. Till 2019, 400 sets of Diamond rock booms have been applied in the markets of China, Russia, Pakistan and Laos and received good commends. It can fit to excavators from 40tons to 180tons, particularly suitable to heavy duty excavators above 80tons.

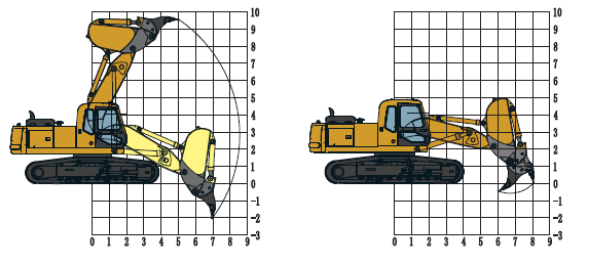

Technical Parameters ( RB-2 Series of Combined Rock Ripper Arm and Boom)

(Remark: Special limiting block design well protecting the arm cylinders, and boom steels are treated by quenching or hardening technology to avoid cracking problems in the extremely cold weather)

Model | RB40.2 | RB70.2 | RB90.2 | RB120.2 |

Fit to | 50tons± excavator | 70tons± excavator | 90tons± excavator | 120tons± excavator |

Max. Digging Height | 7280mm | 8010mm | 9200mm | 10500mm |

Max. Digging Depth. | 1800mm | 1930mm | 2020mm | 3050mm |

Max. Digging Radius | 6790mm | 7980mm | 8100mm | 8550mm |

Ripper Length | 1600mm | 1710mm | 1710mm | 1650mm |

Gross Weight | 19600kg | 29000kg | 33000kg | 44000kg |

Adapter | 103-8114 | R550STQHD | R550STQHD | R550STQHD |

Teeth | 4T5502, D9 | 6Y3552, D11 | 6Y3552, D11 | 6Y3552, D11 |

Boom Cylinder | Double | Double | Double | Double |

Arm Cylinder | Single | Single | Single | Double |

Arm Cylinder Rod Diameter | 150mm | 170mm | 140mm | 150mm |

Bucket Cylinder Rod Diameter | 160mm | 180mm | 180mm | 160mm |

Remark:

①The parameters above mentioned are for reference only because the frame dimentions of different excavator models varies.

②Max. digging distance does not mean Max. effective working distance.

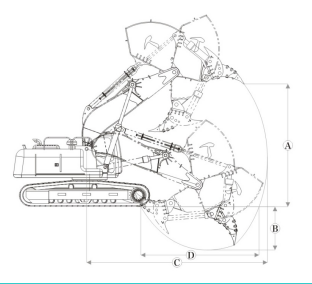

Technical Parameters ( RB-J Series of Combined Rock Ripper Arm and Boom)

Item | Specification | RB30J | RB40J | RB70J | RB90J | RB120J | |

1 | Gross Weight | 15200 kg | 20200 kg | 28000 kg | 33000 kg | 45000 kg | |

2 | Boom Weight | 6000kg | 8000kg | 11000kg | 11000kg | 20000kg | |

3 | Boom Length | 4900mm | 5100mm | 5500mm | 6000mm | 6300mm | |

4 | Arm Weight | 7500kg | 10500kg | 14300kg | 19300kg | 22300kg | |

5 | Arm Length | 4200mm | 4500mm | 5100mm | 5300mm | 5300mm | |

6 | Ripper Weight | 1700kg | 1700kg | 2700kg | 2700kg | 2700kg | |

7 | Ripper Length | 1750mm | 1750mm | 1900mm | 1900mm | 1900mm | |

8 | A | 6500mm | 7000mm | 8200mm | 8800mm | 9800mm | 8800mm |

9 | B | 1800mm | 2000mm | 2200mm | 2100mm | 2200mm | 2100mm |

10 | C | 6400mm | 7100mm | 7500mm | 9000mm | 9000mm | 9000mm |

11 | D | 4500mm | 4800mm | 5000mm | 5800mm | 6000mm | 5800mm |

Remark:

√ The parameters above mentioned are for reference only because the frame dimentions of different excavator models varies.

√ Max. digging distance does not mean Max. effective working distance.

Integrated Rock Ripper Arm (Rock Ripper Boom, Rock R...

Model Selection between Integrated and Combined Rock...

Other Excavator Rock Boom (Hooking and Prying Rock B...

Applications of Rock Boom Products