Excavator Undercarriage Parts and Accessories

Excavator Undercarriage Parts and Accessories

TEL:

+86-186-6891-6700Sprockets, Travel Motors, Driving Wheel and Idlers

SUNTON unequivocally favors a non-weld-on sprocket design, but a bolt-on sprocket system for perfect track pitch alignment. Sprockets are precisely machined and bolted onto the axial. This concept ensures a perfect alignment of each sprocket across the axial, a critical criterion for the longevity of the track chain.

The sprockets and axles of the driving wheels and idlers are equipped with 2 bearings for each side which are skeleton floating sealing ring instead of rubber sealing, which ensure the driving system and idlers have strong performance on heavy duty applications and much longer life time.

SUNTON owns the patent of realizing different speeds of track chains running on each pontoon. This technology could greatly alleviate the torque that builds rapidly when undercarriages turning on firm material.

The solid sprockets, 30mm thick, axles or shafts, rollers and bushings (embedded within the rollers) are made from high tension steel, very thick plates, to match the hardness of the track chain rollers which helps in reducing the frequency of replacement and costly downtime. Rollers travel on a strip of wear resistant steel track, preventing it from premature wearing to the pontoons.

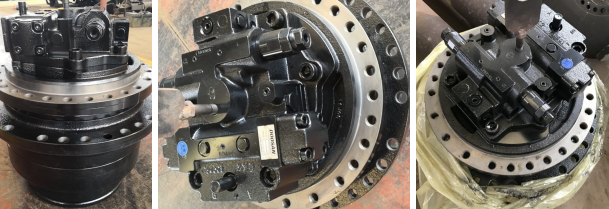

The travel motors are Doosan TM70VC, TM60VC or TM40VC travel motors, SUNTON usually choose much stronger travel motors to propel the marsh excavators, compare to conventional excavators. For example, the travel motors on 20tons marsh excavator are usually the travel motors on a 34tons conventional excavators. This can guarantee the marsh excavator can be applied to tough conditions and have stronger propelling power when the machine works in thick mud or swamp lands etc.

Excavator Undercarriage Parts and Accessories

Heavy Duty Tracks, Chains, Links, Rollers and Pins e...

Chains for Industrial or Agricultural Machinery

Heavy Duty Track Shoes or Cleats